What is Desuperheater

A desuperheater could be a device that cools down the superheated refrigerant (gas that’s at a temperature on top of its saturation temperature).

The temperature of this gas is reduced by spraying droplets of water into the flow of the superheated gas.

Most desuperheater applications scale back the temperature of steam generated by high pressure/high temperature boilers to levels needed in method operations.

The primary operate of a desuperheater is to lower the temperature of superheated steam or different vapors.

Desuperheaters ar crucial parts utilized in the thermal management of warmth from power generation sources to industrial uses in Refrigeration and air-con.

How

Desupeheater works

When

we superheat steam, its not that precise so we essentially overheat

the steam and then cool it down to a precise temperature by injecting

water. This is called an attemporator. But sometimes, we are done

with the superheated steam but need more saturated steam downstream

so we inject water to remove all superheat and generate steam with

it. THis is called a desuperheater

Its the precise same assembly, however the name simply varies supported what quantity superheat is removed.

http://www.maniks.com/desuperheater.html

Typically

an attemporator may just be a couple of valves and a nozzle going

into the steam header.

You simply take a temporary workererature measure and inject water till you hit saturation temp for the pressure you’re at.

I ought to conjointly note that the water used should be very pure.

It can have no solids (dissolved or suspended) in it because the water will immediately turn into steam and the solids will drop out and corrode the steam header or downstream equipment.

Installation

of Desuperheater

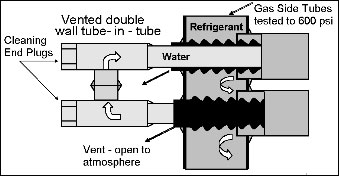

The Desuperheater warmer is put in before the condenser and therefore the oil extractor.

The refrigerant travels through the series of tubes within the Desuperheater before coming into the condenser.

Maniks has a wide range of desuperheaters as they provide precise refrigerant temperature control for various applications in boilers, chemical, oil & gas process plants, etc where the available refrigerant is at superheated conditions.

Normally the Desuperheater Water heater is designed considering the hot water requirement for the processes. When needs of hot water & refrigeration are not simultaneous, a ” Recirculation ” type system is provided wherein hot water is generated, stored & maintained in an insulated tank. This hot water then can be utilised as and when required.

The Desuperheater warmer are often simply retrofitted on reciprocatory, scroll or screw type chillers.

Maniks

is the most reputed Indian brand with a history of 30 years for

manufacturing valves and other devices used in applications of

Refrigeration and Air Conditioning. The company was started

Shekhar Kulkarni, an IIT Mumbai alumnus, with a vision to substitute imported products with Indian make products.

The primary aim was to supply reliable merchandise with wonderful quality and repair.