What is Desuperheater?

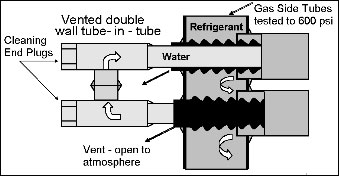

A desuperheater in the context you’re referring to is an add-on (secondary) heat exchanger that transfers otherwise wasted heat from an air conditioner’s hot gas line to a storage water heater. It requires expert installation skills and additional plumbing between outdoor unit and storage tank. It provides “free” hot water. Whether or not it may save more than it costs depends on climate, building cooling load and local energy prices.

Purpose of desuperheater

The

hot water generating component of a geothermal system is called

adesuperheater. It is merely a pump and a heat exchanger that is

plumbed in such a way so as to carry waste heat away from the

refrigeration cycle and into your water heater.

Maniks has a wide range of desuperheaters as they provide precise refrigerant temperature control for various applications in boilers, chemical, oil & gas process plants, etc where the available refrigerant is at superheated conditions.

The general intention of this device is to provide effective and continuous heat transfer between gas and water. And very very effective desuperheater application and design says that costly problems to be avoided, which includes general wear of downstream piping and equipment, long startup and shutdown times, and reduced process efficiency.

http://www.maniks.com/desuperheater.html

Desuperheater Benefits:

1) Heating water with a desuperheater water heater costs about 95 percent less in a cooling dominated climate, and up to 80 percent less in a heating dominated climate, as compare to heating your domestic water with an electric, oil, or propane fired hot water heater. Today the cost of natural gas savings is about 15 percent less, not as drastic a savings as the others, but saving on your bills is still saving on your bills!

2) In the summers, heating your domestic water is “completely” free. This is because the heat that is being extracted from your household devices is transferred into your hot water tank. Since this extra heat from inside of your home devices was going to be rejected (i.e. thrown outside) into the earth anyway, putting it into your hot water tank instead is free.

Maniks is the most reputed Indian brand with a history of 30 years for manufacturing valves and other devices used in applications of Refrigeration and Air Conditioning. The company was started with a vision to substitute imported products with Indian make products. The aim was to produce reliable products .

Customers consistently always choose to partner with us because we are:

Innovative — delivering technology to provide economic solutions

Responsive — exhibiting passion, speed and agility

Conclusion:

Desuperheaters are very necessary components used in the management of superheated gas from power generation sources to industrial uses of gas. This structure of desuperheating the refrigerant represents the vast majority of desuperheating applications.The nozzles inject a small amount fine spray of cooling water onto the superheated refrigerant, which causes the water to be converted into gas, hence reducing the quantity of superheat.